|

How It Works

Operation

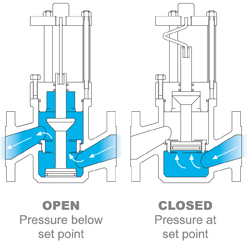

The Buckling Pin Valve is one of the most precise, accurate and dependable valves used in emergency shutdown for isolation and flow diversion. The valve features a clapper, disk, piston or plunger in an open position, restrained from movement by a slender, centerless ground pin that obeys Euler's Law. The pin is external to the system being protected and is held firmly on both ends. The pin is engineered to buckle at an exact set point from an axial force applied by the system pressure acting on an unbalanced piston stem area. When the pin is buckled, the valve is instantly closed. The pin is made of corrosion resistant alloys whose modulus of elasticity is constant over the ambient temperature range experienced by the valve. Each Buckling Pin valve we produce is self-contained and self-actuating.Euler's Law

Euler's Law of Compressed ColumnsEuler's Law determines the buckling point of the Pin.  By using Euler's Law of Compressed Columns, the pin's diameter, length, and material can be determined and the set point accurately predicted, every time. The pin dimensions must be precise; we control the pin diameter by measuring to 5 decimal places and the length is measured to 4 decimal places, insuring the necessary quality control and set point repeatability. The modulus of elasticity of the pin material is the only variable due to ambient temperature. Using materials that have a minimal change in modulus of elasticity in the temperature range where the valve will be in service solves this challenge. Because the pin is in compression, it can never exceed the elastic limit until it buckles by Euler's Law. Pulsation is not a factor and the pin can never fatigue or fail prematurely. Since the pin is external to the system, pin corrosion in not a concern. A corrosive environment outside of the system you are protecting is no problem since the pin is made of a non-corrosive material. Multiple Capabilities

• There are no limits to valve size or set points. Buckling Pin valves have been successfully built as small as 1" to 18" diameter. Pressure set points can be set from 5 PSI to as high as 6,000 PSI. Vacuum can be set as low as 1 psi.• It can be designed to sense system pressure or differential pressure. • It can be designed to handle corrosive and dangerous fluids and gases with minimal operating expenses and no environmental concerns because the systems' integrity is not compromised when resetting the Buckling Pin Valve. • It can be made of special alloy materials, plastics or be glass lined to meet your unique corrosive situation. • The valves may also be equipped with a proximity sensor to alert the operator of a valve closing. • The body of a Buckling Pin isolation valve can also be a quarter-turn ball or butterfly valve. In all types, the valve goes to a closed position in only milliseconds. Summary

Several features of the Buckling Pin valve should make it your first choice for system isolation. The Buckling Pin valve is not subject to premature failures. It is much more accurate that anything else on the market, especially at extreme pressures (low or high). The pin is independent of system temperature and corrosion factors. It offers you flexibility and protection. The system can sense upstream or differential pressure.The Buckling Pin valve will offer substantial savings in operating and maintenance costs by avoiding premature failures, not breaking into the integrity of your system to reset, not exposing you to environmental concerns, quick resetting when you do have to change the pin, and preventing loss of your valuable product. Our customers who have experienced the advantages of Buckling Pin valves, have found them to be a better overall value when compared to other products on the market. For additional information on Buckling Pin Valves, or specific answers to your questions, contact Eddie Loomis at 405.789.1884. Valve Maintenance

There are two ways to check the piston movement.(1) Remove the pin and apply pressure to the valve of no more than 10-20% of the set point. If the piston moves, the valve is in good shape. (2) To test under pressure, turn the pin holding nut one turn, no more. If the piston moves, the valve is reliable. Tighten the holding nut. You are now assured of opening at set point. The pin is never a concern. It obeys Euler's Law. If the piston does not move, remove the top assembly by loosening the bonnet bolts. (The top plate should never be removed). Remove the piston and replace the elastomer seals; reassemble and reset the Pin. Check to make sure the pin is not damaged or bent by rolling on a flat service, the pin will have an infinite life if not damaged or bent. |

Above:

Pin buckles at set point from an axial force applied by the system pressure acting on the piston. Valve Certification Tests

Certification tests are done on all valves before they leave our facility. The ASME standard calls for set point variation of +/-5%, but rarely is the deviation over +/-3% from set point; +/-1% is common. After successful valve testing, three pins are tested on the Tinius Olsen machine to determine a load vs time curve for the archives. This insures consistency between pin material lots.Special machines are used to cut the pins to length perpendicular to the pin axis and polish the cut ends. All pins are tagged with all pertinent information required to match the pin to the valve. All valves have a serial number stamped on the bonnet and valve label. New pins may be ordered with just the valve serial number. Pin orders before noon on business days can be shipped to you on the same day. Applications

• It has many uses where a non-resetting pressure isolation valve is desired.• The Buckling Pin isolation valve will save you operational expenses, reduce downtime and eliminate environmental concerns. • It will give you an immediate visual indication that you've had an isolation without the need to take apart your system – as you have to do with others, where broken disc indicators are not reliable. • You can reset the Buckling Pin valve in a matter of minutes and be back in business. • You will be able to operate your system closer to maximum operating pressures without the fear of premature isolation. View More

Visit Buckling Pin Technology

|

|---|